Field Experiences and Capabilities

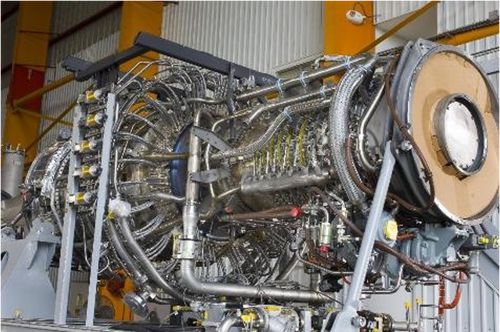

G.E. Frame 7FA HEAVY DUTY GAS TURBINES

Location: Various Sites Middle East KSA,UAE

GE Frame7FA

TEAM PROJECT EXPERIENCE:

- Major Inspection (M.I.),

- Hot Gas Path Inspection (HGPI)

- Hot section Upgrades,

- Turbine blades/Shrouds replacement

- Rotor Replacement

- Bearing Inspection

- Combustion Can replacement

- Fuel Nozzlesreplacement/upgrades

- Auxiliary Inspection

- Control SystemUpgrade

- Instrumentation upgrades/calibration

SERVICES PACKAGES OPTIONS:

- Combustion Inspection(CI) -8 DAYS

- Hot Gas Path Inspection (HGPI) – 15 DAYS

- Major Inspection (MI) – 21 DAYS

- Flange to Flange, 2 shifts

ENGINE: G.E. Frame 6B/FA HEAVY DUTY GAS TURBINES

Location: Various Sites Asia (Malaysia, Indonesia, Korea, Japan Etc.)

GE Frame6B

GE Frame6FA

TEAM PROJECT EXPERIENCE:

- Major Inspection (M.I.),

- Hot Gas Path Inspection (HGPI)

- Hot section Upgrades,

- Turbine blades/Shrouds replacement

- Rotor Replacement

- Bearing Inspection

- Combustion Can replacement

- Fuel Nozzles replacement/upgrades

- Auxiliary Inspection

- Control System Upgrade

- Instrumentation upgrades/calibration

SERVICES PACKAGES OPTIONS:

- Combustion Inspection(CI) – 6 DAYS

- Hot Gas Path Inspection (HGPI) – 11 DAYS

- Major Inspection (MI) – 15 DAYS

- Flange to Flange, 2 shifts

ENGINE:G.E.Frame6B/FA HEAVY DUTY GAS TURBINES

Location: Various Sites In The Oil & Gas Facilities, Middle East, Australia, Etc. (Qatar Gas, Kazakhstan LNG)

Modular Change

TEAM PROJECT EXPERIENCE:

- Major Inspection (M.I.),

- Hot Gas Path Inspection (HGPI)

- Turbine blades/Shrouds replacement

- Rotor Replacement

- Bearing Inspection

- Combustion Can replacement

- Fuel Nozzles replacement/upgrades

- Auxiliary Inspection

- Control System Upgrade

- Instrumentation upgrades/calibration

SERVICES PACKAGES OPTIONS:

- Combustion Inspection(CI) -6 DAYS

- Hot Gas Path Inspection (HGPI) – 11 DAYS

- Major Inspection (MI) – 17 DAYS

- Flange to Flange, 2 shifts

G.E. LM2500 AERO DERIVATIVES GAS TURBINES

Location: Kuwait, Japan, Australia, TEPCO, APLNG, QCLNG, GLNG, etc.)

LM2500 DLE

LM2500 SAC

TEAM PROJECT EXPERIENCE:

- Level 1 Maintenance

- Level 2 Maintenance

- Boroscope Inspection

- Auxiliary Inspection

- Control System Upgrade

- Instrumentation upgrades/calibration

SERVICES PACKAGES OPTIONS:

- Level 1 Inspection

– Auxiliary Inspection

– Auxiliary Inspection - Level 2 Inspection

- Flange to Flange, Single shift

G.E. LM6000 AERO DERIVATIVES GAS TURBINES

Location: Australia (Wheatstone LNG)

Boroscope Inspection

TEAM PROJECT EXPERIENCE:

- Level 1 Maintenance

- Level 2 Maintenance

- Boroscope Inspection

- Auxiliary Inspection

- Control System Upgrade

- Instrumentation upgrades/calibration

SERVICES PACKAGES OPTIONS:

- Level 1 Inspection

– Auxiliary Inspection

– Auxiliary Inspection - Level 2 Inspection

- Flange to Flange, Single shift